Receive real-time results on pallets and goods detection in warehouses for logistics management.

Improve the efficiency of logistics parks and warehouses with Parquery's smart solutions. Optimize processes at loading bays, arrival areas, goods handling, and in truck waiting areas:

Contact us, and we’ll show you real-time results and structured analytics you’ll receive with our warehouse management solutions!

Our partner vi2vi Retail Solution GmbH approached us to develop a pallet management solution for one of the warehouses of an international retail corporation. Their goal was to streamline the goods-receiving process and take a step towards digitizing the supply chain.

Goods receiving area with a telescopic ceiling-mounted camera.

Overhead surveillance cameras capture the goods receiving area of the large warehouse. These were upgraded with Parquery's artificial intelligence (AI), which detects pallets in the camera images and extracts real-time usage and analytical data of each pallet lane.

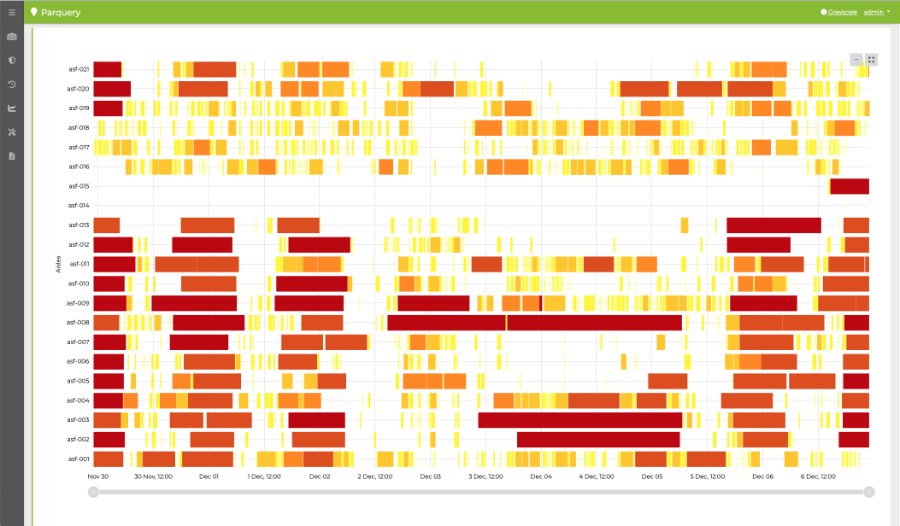

The real-time information on empty aisles and vacant space is critical to on-site staff. The statistics and analytics proved valuable to warehouse operations and management. They shed light on which lanes are fully utilized and which are underused.

Typical queries include: Which aisles are occupied and for how long? Which are the high-turnover aisles (hotlanes)? And why?

Answering these questions with an automated computer vision solution adds value to existing infrastructure while helping to optimize warehouse logistics, for example, by directing goods that need to be distributed quickly to hotlanes where they can be turned over quickly.

Warehouse management dashboard - high-turnover and slow-moving goods aisles can be identified at a glance. The manager can then delve into a deeper enquiry with Parquery's analytics.

Camera view of the goods receiving area. Due to contractual agreements, sketches are shown in place of actual footage.

Our main office is located in Geerenweg 2, CH-8048 Zurich, Switzerland

info [at] parquery.com

+41 44 501 39 19 (8:30am - 5:30pm CET)

Upon receiving your request, we will get back to you shortly.